Water Recovery Solutions

WRS TM Water & Energy Recovery

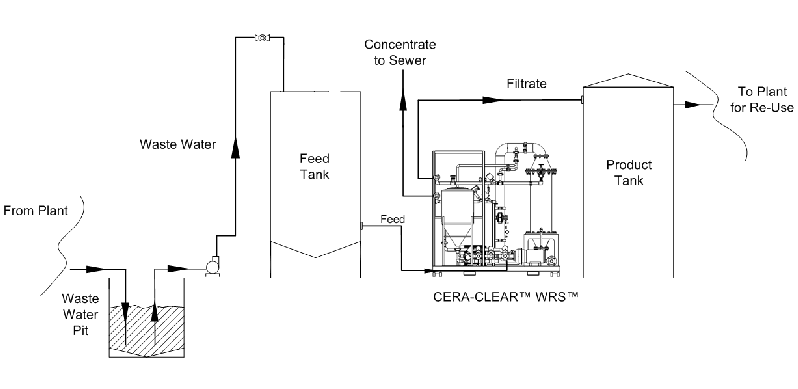

In this scenario, a stream is circulated at high velocity through the CERA-CLEAR ceramic module. The liquid is separated through the ceramic elements and filtrate is discharged into the product tank for the plant reuse at temperature resulting in water and energy recovery savings to the plant. The CERA-CLEAR processes the water at the temperature it was received at. So if the water is 150F when received and 75% of the water is being recovered for reuse in the plant, then 75% of the water less the makeup water does not have to be heated up from the city water ofr well water ambient temperature to the desired temperature. This significantly lowers the carbon footprint and lessens the impact to the environment demonstrating commitment to being good stewards of the environment.

The WRS systems track carbon offset savings from the reduction in fuel acquisition in as well as fuel costs

Our systems takin in to acccount the necessary design criteria to deliver real measureable savings that is tracked and reported real time to a digital dashboard for engineering and management.

Below is a real-world example of savings being delivered for a modest sized commercial laundry